TECHNICAL INFORMATION

Thermal Expansion Joint Profiles

In ceramic, granite, porcelain, stone, glass ceramics, concrete and marble tiles, terrazzo applications, thermal expansion joints are needed to absorb due to natural movement of mergences.Temperature differences, water and moisture cause expansion and shrinkage at sealers. All tiles is shrinked due to desication and cooling. Also, dynamic structural loads cause vibration and movement of tile applications. For these reasons joint design is very important for the service life of the coating.

If expansion joint is not used on applications of tile, ceramic, granite and marble, internal stresses caused by expansion and shrinking cycles may cause many problems. If very strong glued ceramic and granite coatings, in coatings cracking will occur in the obvious way. If it is not good bonded, this movement shows itself separated from the reinforced concrete or screed. It formed in the interior and exterior cracks that cause moisture transfer and additional damages. Thermal expansion joints are usually applied on tile and screed applications. Crack control joints are created by cutting or during screed cast.

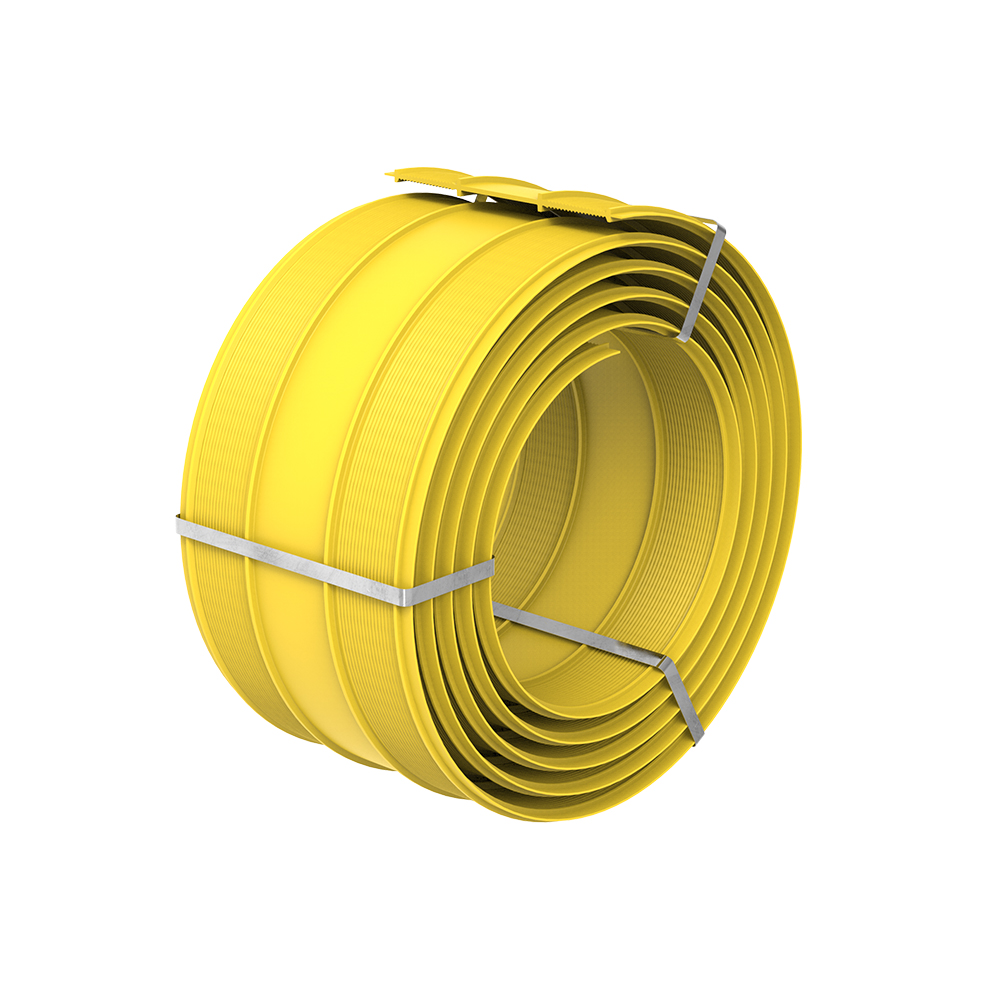

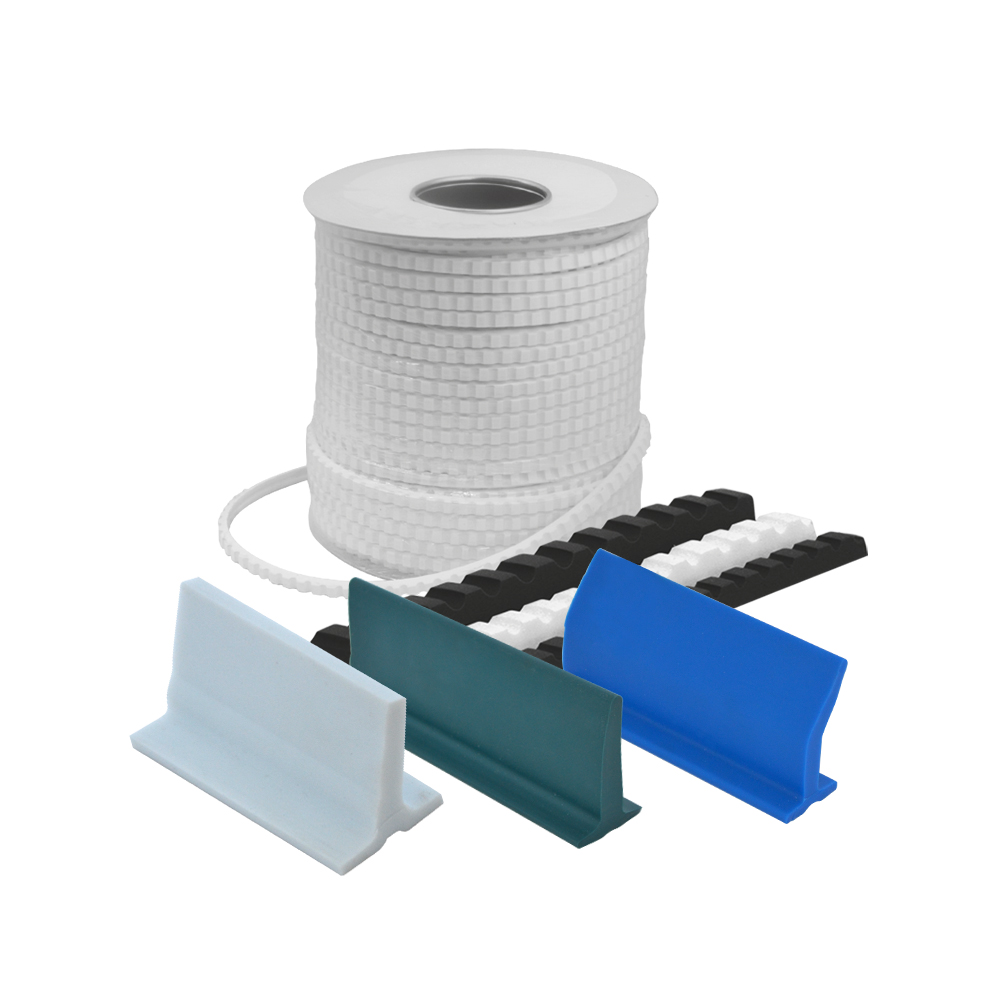

To create these joints according to ASTM C 920; silicone, polyurethane, polysulfide sealants can be used. Also, professionally manufactured in factories stainless and aluminum footed neoprene or PVC thermal expansion joints are used.

All aluminium & neoprene, stainless & neoprene and PVC thermal expansion joint profiles are produced in Arfen Factory.

In case of recommended for thermal expansion joint widths and range of applications, if you contact with our company, we want you to specify that we will be happy to help you.

Please click here to get details on the comprehensive products and services ARFEN THERMAL EXPANSION JOINTS.

Türkçe

Türkçe English

English Русский

Русский