About Dilatation Profiles

The dilatation profile is a general name given to the definition of the profiles used to create a flexible zone in the building spaces called dilatation. Dilatation, a word that has passed into our language from French, means to dilate, to expand. Dilatation profiles are also the name given to the profiles attached to both sides of the structure and the elastic systems between them in order to pass these expansion gaps elastically.

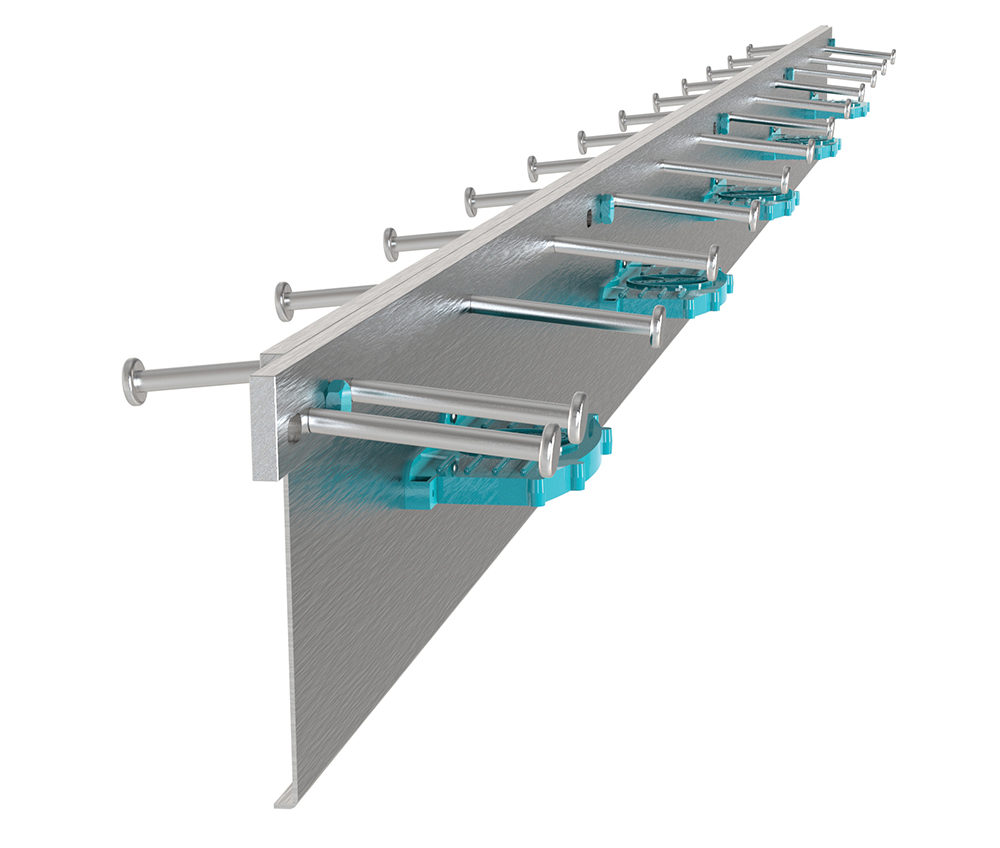

In general, in the first years of use in the construction industry, two iron angles and elastic filling material filled between these angles; as a result of the development of production methods over time, the developments in earthquake regulations and the increase in dilatation gaps due to these developments, the use of aluminium profile, the use of EPDM suppositories, the use of soft PVC suppositories and thermoplastic elastomer suppositories in the use of dilatation profile have increased. Again, in parallel with the changes and developments in building materials, the use of stainless steel in dilatation profiles has increased considerably.

Especially in the last quarter of the 20th century and the beginning of the 21st century, in large-scale projects, buildings occupy very large areas, some of these structures are built as high structures and connected to less-storied structures. Although it does not attract the attention of people who are not engineers or architects, however, dilatation profiles offer comfort to the user such areas as separate floor, wall and ceiling coverings from each other in many projects such as shopping malls, airports, business centres, public buildings and hospitals, are used in wet areas and terraces, and are used in parking lots together with large-scale structures.

Dilatation profiles should not be considered as a stand-alone solution. Those are the needs of the building in order to meet the demands of the projects before and after its construction;

Crossing the dilatation space with a certain movement capacity.

Compatibility with waterproofing solution when necessary.

The structure must be resistant to moving loads (pedestrian traffic, vehicle traffic, forklift, etc.) suitable for its purpose.

Fully compatible with floor covering height.

Responding to requirements such as fire insulation when necessary.

The building should be compatible with the construction method and be suitable for coordination.

In general, the gaps where dilatation profiles will be applied start from at least 30 mm, and it reaches a value where the value is used whichever is greater than the dilatation gap calculated according to the earthquake code and the minimum gap ratio coming from the constructive principles.

Depending on the rigidity of the structural system of the building, the choice of the reinforced concrete system, the earthquake zone of the building, and the height of the building, dilatation gaps should be spaced as such as 3, 5, 10, 15, 20, 25, 30, 40 cm today. In new generation structures made with seismic isolators, these gaps sometimes increase up to 150 cm and 200 cm.

Steel + rubber jointed systems are made in such spaces. An important point here is to complete the building application and the construction of the project to a higher value, even if the gaps appear to a fractional extent in the calculations. For example, in a structure where the largest opening in the calculations is 137 mm, the project engineer completes this to the closest value of 150 mm and designs the project according to this measurement. Otherwise, during the construction of the project in the field, there will be great difficulties in material supply both during the application and leaving the dilatation gap.

Especially in multi-functional buildings consisting of many blocks, a part of the building is used for parking purposes, while on the upper floors some area can be used as a restaurant, some area can be used as a common WC, and some area can be used as a passage corridor.

Since the needs of each of these types of spaces are different, dilatation solutions are also different. It is inevitable to use different dilatation profiles in areas with different dilatation solutions.

For this reason, during the project phase, the project engineer and the authorities of the dilatation profile producer companies determine the needs of the project. Especially in dilatation gaps of 10 cm and above, it has been proven by firefighting reports in some international fires that the dilatation gap has a chimney effect during the fire. In addition, it is necessary to examine the waterproofing separately from field applications in these regions and ensure its continuity.

While choosing the dilatation profiles, the floor-wall-ceiling coverings heights, types, corner details should be considered very well and the purpose of use of the building should be taken into consideration. For example, while the first priority in an industrial structure is the load carrying capacity of the profile, the first priority in a healthcare structure may be hygiene and comfort of use. When switching to parking lot applications, models made of rubber + steel or rubber + aluminium can be selected, which are suitable for vehicle traffic and do not make noise.

After all types are selected, dilatation profiles are put in place as the covering material installations are made in accordance with the work program of the project.

An important issue here is the correct selection of the bedding material used during the elevation of the dilatation profile and the anchoring materials used to connect the leg profiles of the dilatation systems to the ground. While mostly steel and chemical anchors are used in heavy load profiles, epoxy mortar or grout mortar is used as bedding material.

While mounting the dilatation profiles, it should be prevented that the dilatation profile presses into the gap and it should not be mounted as a console. If the dilatation gap is more than the clear opening of the selected profile, the profile type and opening should be changed, and a dilatation profile with an upper size and opening should be used.

Dilatation profiles are generally produced in lengths of 3 to 4 meters, and middle inserts are produced in lengths of 15 - 25 meters, to be finalize as continuity.

Considering seasonal effects in exterior dilatation profiles, a gap of at least 3 mm should be left every three meters throughout the dilatation, thus preventing longitudinal corrugation in hot weather.

PVC-based inserts should not be used on the exterior applications. As PVC material, it elongates and shortens in hot and cold temperatures and hardens in cold. Therefore, thermoplastic based inserts should be used in such places.

Aluminium thermal expansion coefficient is C 23 x 10-6

The general elongation formula in thermal changes;

ΔL=L.(T2-T1).C

L : Profile length

C: Elongation coefficient of the material

T2: The highest temperature seen

T1: The lowest temperature seen

With this formula, if a place that can be -5 °C in winter and a maximum of 37 °C in summer;

ΔL=3000. (37-C-5). 23x10-6

ΔL=2,89 mm = 3.00 mm

In the hope that this article will be a general enlightening text about dilatation profiles for the readers, we will share more protection and isolation methods of dilatation profiles against fire in our next article.

Türkçe

Türkçe English

English Русский

Русский