What is Slab Concrete Flooring?

Slab Concrete flooring is the one of the essential structure applications. Slab concrete flooring that is sometimes used a part of Construction or sometimes used for full settlement has many benefits, nevertheless, it can cause several problems if the application technical details are not observed. Correct application details are specified graphically at primarily ACI (American Concrete Institute) and other EU publications documents.

It is necessary to refer about the behavior of the elements that form the slab concrete during application in order to understand the failures in slab concrete applications. Basically slab concrete is the operation without using reinforcement bar on the extensive Ground. Concrete, which is poured as fluid, is complete hardening period after its forming elements chemical reaction finishes. The two main components that react and are came out as a result of the chemical reaction are the main cause of problems in Slab concrete. These main elements are water and temperature.

Temperature that come out as a result of chemical reaction, causes the water in the concrete mass to evaporate and the concrete slab begins to shrink towards its inner center. Slab concrete is supposed to be allowed to move since this shrinkage makes the concrete mobile within itself. There are both traditional and technological applications to ensure this movement ability.

In the traditional method, the concrete surface is cut by hand-saw machine at certain intervals at a depth of ¼ of the poured concrete thickness in order to ensure the concrete mobility. However, this traditional method has many disadvantages. The joints cut by hand with the help of a saw remain vulnerable to external influences. External forces may damage these joints edged created in the slab and the flat structure of the concrete surface may be disrupted. In addition, joints that aren’t made at the required depth do not allow full movement of the concrete and may cause capillary cracks. This defect, which starts as a capillary crack at the bottom of the concrete, expands until it reaches the surface and causes the formation of wide-span cracks on the concrete surface.

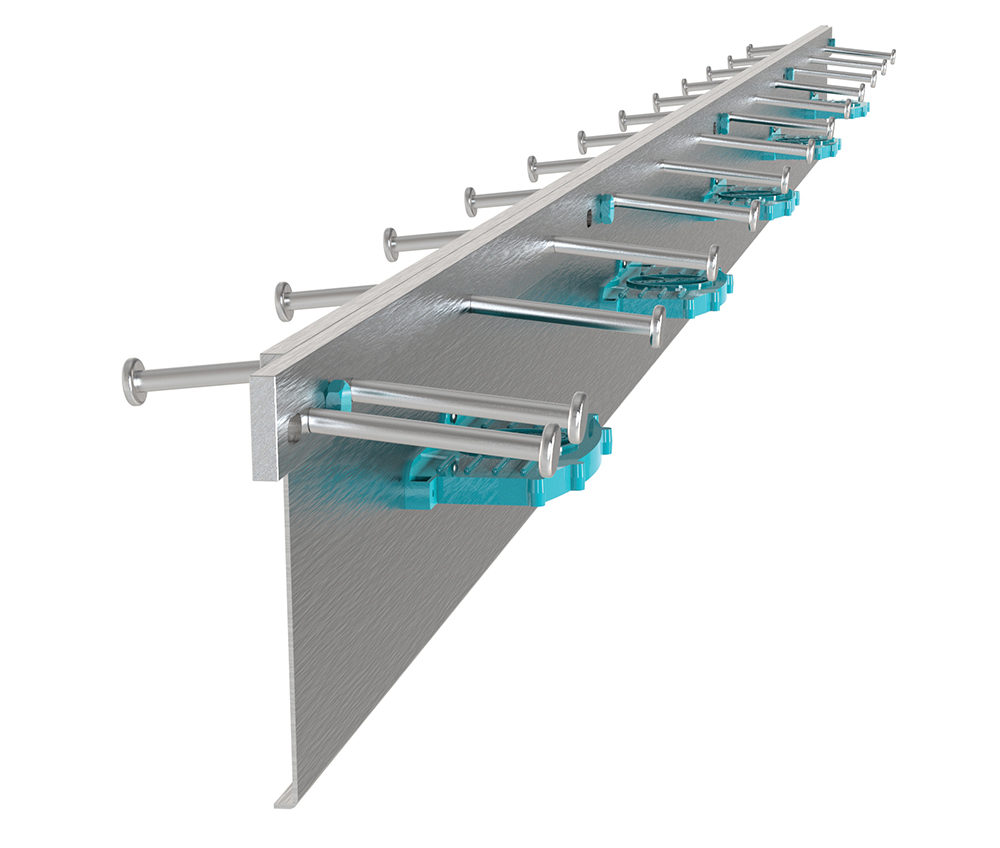

ACI had started concrete behaviors researches for the perfect concrete surface in the early 1950s as a result of the disadvantages caused by the applications made with the traditional method. This system, which adapts to the movement of the concrete and protects the edges of the joints with steel profiles, is called “armoured system”. This steel armoured system, which is applied at certain intervals after the concrete casting, fully merges with the concrete and allows the slab concrete to move in the desired direction. It forms the joint itself in the cold drawn steel profile by taking the shrinkage movements of the concrete on itself. It also protects the joints formed with the help of cold drawing slats while the system forms its own joints. Thus, the joint edges are protected against external impacts throughout its lifetime.

Arfen provides the production and supply of different types of floor joint systems such as sinusoidal or straight in line with approved and developments made by ACI. Joint systems can be produced in black steel, galvanized or stainless steel within the scope of the needs of the project. Different types of products are supposed to used for different concrete thicknesses. For this reason, Arfen continues to supply the most suitable product to its customers with 7 different types for 90mm thick concrete to 450mm thick slab concrete.

Türkçe

Türkçe English

English Русский

Русский